Most Visited

Rats In Your Home

Drain Flies

Why Drains Block

Internal Venting

Who`s Drain Is It ?

Drain Surveys

No-Dig Repairs

Drain Location

Drain Rods Stuck

Find A Contractor

Drain Pipe Work

Clay Drain Pipes

Plastic Pipe Work

Pitch Fibre Pipes

Cast Iron Pipes

Concrete Pipes

Drainage Parts

Drain Gullies

Dropshafts

Interceptor Traps

Soil Vent Pipes

Anti-Flood Valves

Manholes

Drain Repairs

Excavations

Drain Lining

Patch Lining

Pipe Bursting

Re-Rounding

Drainage

Investigations

Drain Surveys

Sonar Tracing

Last updated 7 January, 2014

draindmain.com > site map > drainage system parts > backdrops

Manhole Backdrop

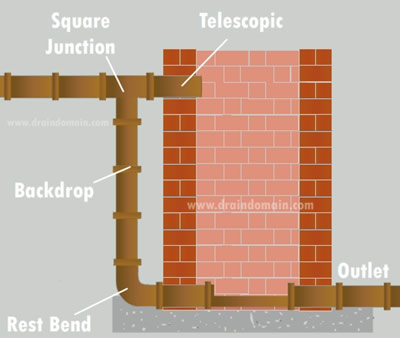

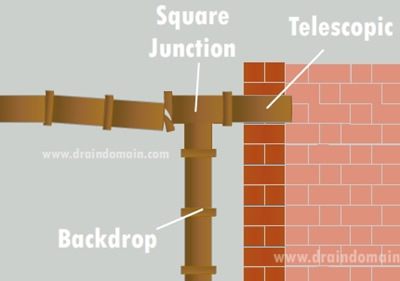

A backdrop is a drop shaft situated prior to a manhole or chamber, the main difference from a standard drop shaft being the telescopic arm that continues through into the chamber wall so as to allow access back into the incoming pipe work as shown in the drawing to the right.

A backdrop is a drop shaft situated prior to a manhole or chamber, the main difference from a standard drop shaft being the telescopic arm that continues through into the chamber wall so as to allow access back into the incoming pipe work as shown in the drawing to the right.

This type of construction allows the higher level drainage to be installed with minimum fall before being connected to the lower level system, however unlike the drop shafts shown at the top of the page all lines are accessible for clearing, surveying and future maintenance.

You do occasionally find a standard or blind drop shafts without the telescopic prior to chambers which are bloody annoying

if you are trying to survey or clear a system.

Defective Manhole Backdrops

Just like any drain system section these shafts can be prone to tree root ingress, if there is too much fall on the incoming pipe work or the shaft becomes blocked for some reason then paper and solids can over shoot the shaft and enter the chamber via the telescopic. This usually results in a build up of waste in the base of the manhole which in time falls into the channel pipe causing a blockage.

For this reason the telescopic's are sometimes fitted with a cap or sealing plate to prevent any over shooting of waste and you often find the telescopic to be constructed from an upward facing bend so that any over shooting waste matter falls back into the shaft.

The backdrop shaft becomes part of the rigid construction of the chamber as it is anchored to the brick work by the telescopic arm and the rest bend at its base. For this reason the most common defect we find on these system is due to settlement of the pipe work that enters the back drop itself.

The backdrop shaft becomes part of the rigid construction of the chamber as it is anchored to the brick work by the telescopic arm and the rest bend at its base. For this reason the most common defect we find on these system is due to settlement of the pipe work that enters the back drop itself.

Typically a large and deep excavation would have been undertaken to install the chamber which means that the last couple of higher level pipes are sat on infill, if this infill was not compacted properly some settlement can occur and because the shaft is rigid the pipe that enters the junction at the top is the first to drop as shown in the image to the left.

The resulting step against the flow of the system causes paper and solids to build up and block the system, the water loss into the sub-soil can undermine the remainder of the shaft and the manhole itself.

Many years of steady and constant water loss can have a serious affect on the brickwork that forms the manhole, washing out the sand a cement mortar and causing walls to bow and move, depending on the ground type the water loss can undermine the chamber causing it to rotate and settle usually damaging the interceptor or pipe work on the outlet.

Repairing Defective Backdrops

If the shaft has root ingress or fractures then it can usually be relined, if the structural damage is severe and the integrity of the the construction of the chamber itself is in question then a full excavation would be required.

Internal Dropshafts

Greatly frowned upon these days, this is where you basically construct a backdrop or drop shaft within an existing manhole or chamber, there is a good argument for them in the right circumstance and good reason for not allowing them on most occasions.

You have just installed 10mtrs of 100mm pipe work at a depth of 400mm and the main line drainage is 2mtrs deep and you need to get the two connected do you; a) hand dig down the full depth, install a junction into the main line drainage and bring up a new shaft, or b) knock a hole through the existing chamber and poke your new pipe through it ?. It is of course human nature or at least drainman nature to take the easy option and knock lumps out of an existing chamber as opposed to digging a 2mtrs deep hole.

The image to the right shows a 100mm internal drop shaft installed in a concrete sectional chamber, the chamber is more that big enough to take the shaft without affecting access however a hole has been punched through the side of the manhole for the pipe work and it has not been sealed afterwards. The bend at the base of the shaft is also considerably higher that the main line drainage and there are no brackets holding the shaft in place, as it is formed from a push fit plastic pipe the whole lot could quite easily become detached and fall into the channel causing a major blockage.

When done correctly in a big enough chamber these things work, the problem is they were seldom installed correctly and they can cause many problems. The main one is safety, modern specifications require and rightly so that if it is necessary to enter a chamber their should be sufficient clearance for the guy and his escape kit to get out quickly if needed, the older manholes are in general tight enough without some clown sticking a 150mm drop shaft in the 600 x 450 neck of the chamber.

Then there is the affect of the works on the manhole itself as usual the lump hammer got preference over the core drill and great chunks of brickwork would go missing, usually down the outlet pipe. The shaft itself was seldom fitted to the brick work with brackets and the bend at the base of the shaft if there was one had nothing in common with the flow of the main line channel and would spray waste and solids indiscriminately over the sand and cement benching, often eroding it in the process.

I have had permission to install internal shafts in recent history, it was a 5mtr deep manhole with a shelf at 2mtrs where it opened up into a good size chamber, we were therefore allowed to install an internal shaft away from the neck of the chamber as long as it was a ductile iron pipe with its outlet entering the flow of the main line drainage at the correct level and angle.

Wall brackets were specified and a stopper in the telescopic were also required with the stopper being anchored to the chamber via a fixed chain. The alternative was a deep dig in a narrow lane in running sand so common sense prevailed.

Wall brackets were specified and a stopper in the telescopic were also required with the stopper being anchored to the chamber via a fixed chain. The alternative was a deep dig in a narrow lane in running sand so common sense prevailed.

Having said that i have tried my luck on a couple of occasions since and had a straight ` We do not allow internal shafts. Full Stop !` thrown back at me. It just comes down to who your asking and in what area of the country you are in.

The image to the right an example of how internal shafts hinder access into manholes and chambers, the chamber was poorly installed in the first place as it is way to narrow for its depth and the step irons are installed in opposite

corners from each other.

Then presumably at a later date somebody turns up and sticks an internal dropper bang in the middle of the shaft restricting access to such a degree that even a drainman with the figure of a racing snake would struggle to get in there. You will also note the lack of brackets holding the thing in place once again.

| related pages - | manhole construction |

| drainage junctions | |

| interceptor traps | |

| find a contractor | |